Good Quality Bouillon Cube Packing Machine - semi-automatic cube tray packing machine – Brightwin

Good Quality Bouillon Cube Packing Machine - semi-automatic cube tray packing machine – Brightwin Detail:

The machine is our new design, it’s suitable for boxing cubes, medicine, cosmetics, and goods etc. It is a semi-automatic multi-layer boxing machine. After the products are arranged, the cylinder will push them into the mold to complete the arrangement.

Specifications

●Thickness 2 mm SUS304 plate, and square tube,

●Mitsubishi PLC control,

●International brands Electrical components (as the Main Components list),

●High speed (120 cubes per minute),

●Easy to install, operate, clean, and repair,

●Just need to change few parts for different size carton.

Parameter

Capacity: 5-10 boxes per minute

Dimensions of the machine: 1800*300*950mm

Layer number: 3

Box size:

24pcs: 127mm*103mm*44.3mm (L*W*H)

12pcs: 103mm*65mm*44.3mm (L*W*H)

The cube dimensions: 50.7mm*30.7mm*13.8mm (L*W*H).

Voltage: 220V 50Hz (customized)

Air consumption: 0.2m³/minute

Power: 500W

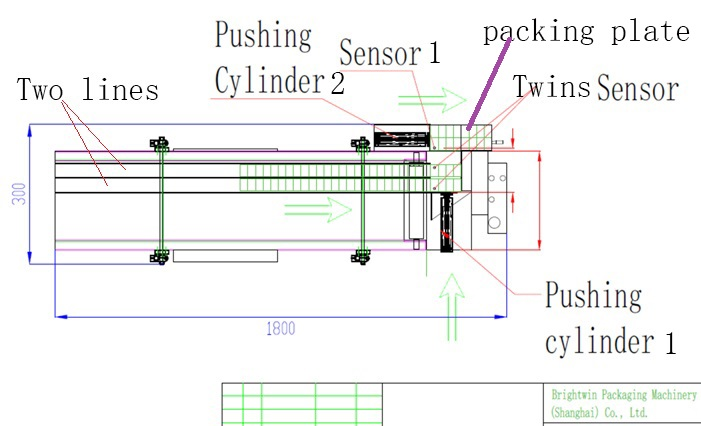

As the following drawing, the cubes come in two lines at the same time. Sensors will be installed at fixed places

Working steps:

1.When the twins sensor detect cubes at the same time, pushing cylinder 1 pushes 8 cubes to the next position.

2.After pushing cylinder 1 finishes twice pushing, sensor 1 will detect cube at it’s position, then pushing cylinder 2 will push 12 cubes to the third position.

3.The Packing plate get down one layer height to wait the second layer and the third layer.

4.When 3 layers collect at plate as the fixed arrangement, packing plate will up back to the origin height.

5.Worker covers a carton over the plate, and rotate the plate by handle, cubes will be packed onto the carton very well.

After sales services:

1.Offer professional operation manual

2.Online support

3.Video technical support

4.Free spare parts during warranty period

5.Field installation, commissioning and training

6.Field maintenance and repair service

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Good Quality Bouillon Cube Packing Machine - semi-automatic cube tray packing machine – Brightwin , The product will supply to all over the world, such as: Malaysia, Denver, Morocco, Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!