Hot New Products Double Side Labeling Machine - Sleeve and shrink machine – Brightwin

Hot New Products Double Side Labeling Machine - Sleeve and shrink machine – Brightwin Detail:

Overview

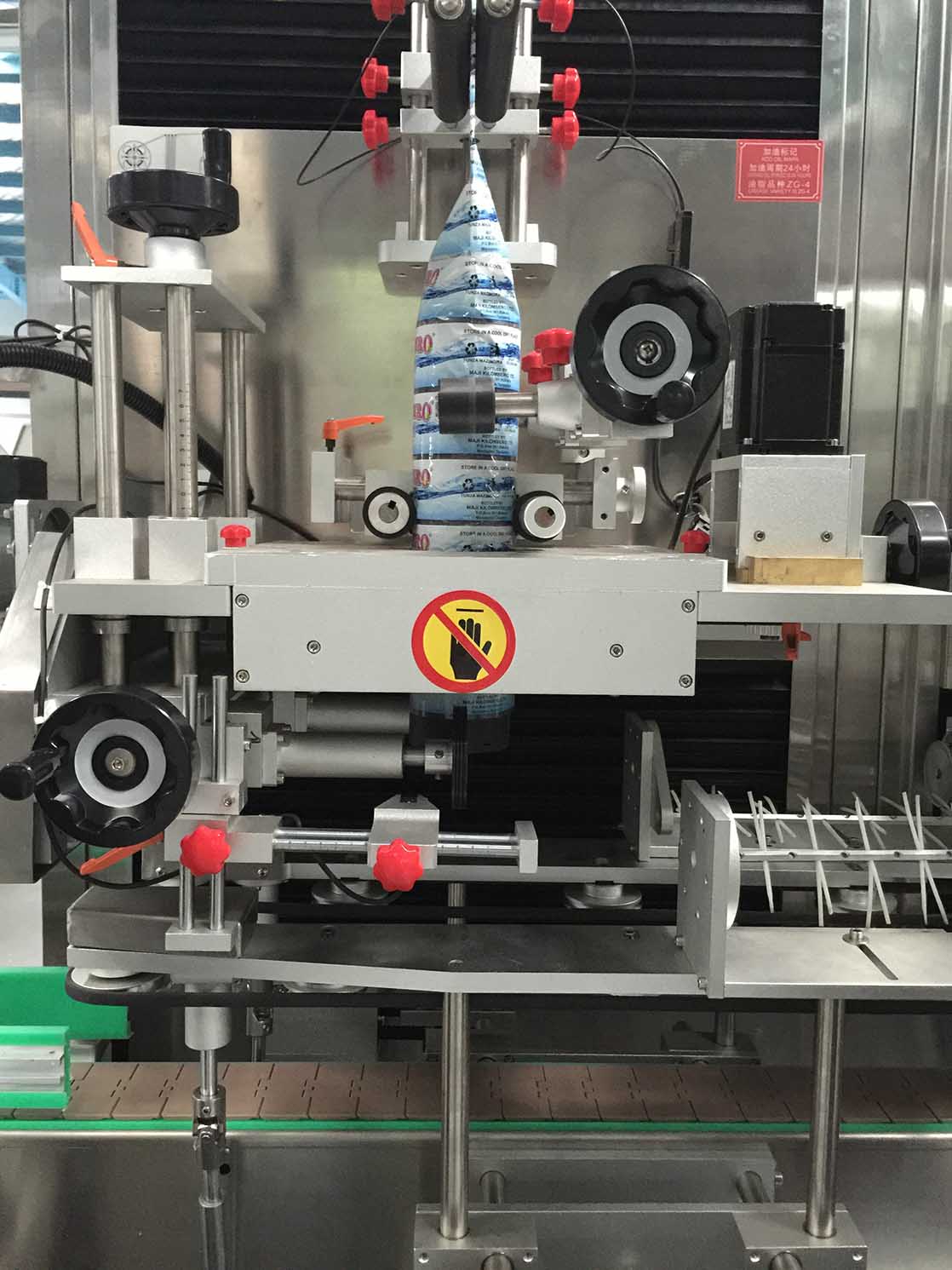

It consist of sleeve machine and shrink tunnel. The sleeve machine can sleeve round labels around bottles, then shrink tunnel shrink the label onto bottles tightly. It is applicable different bottle shapes, and can sleeve bottle neck, bottle body, whole bottle and even bottle bottom.

Feature

1. Can share one machine for different container sizes and label sizes within certain limits by changing some parts.

2. The maximum speed reach 30000b/h

3. It can sleeve bottle neck, bottle body and whole bottle etc.

4. Suitable label material: PET/PVC/OPS

5. Japan-made motor controls synchronous cutting system to ensure long use life of cutting tool and high precision label.

Parameter

| Model | Specification |

| Main engine size (length*width*height) | 2000L x 950W x 2000H(mm) |

| Main engine production speed | 50-500b/m |

| Main engine power supply | 220v/110v etc(customized) |

| Bottle/Can Flat Width | customized |

| Bottle/can materials | Glass, metal, plastic |

| Label length | 25mm-280mm |

| Label thickness | 0.03mm-0.13mm |

| Label material | PVC.PET.OPS |

| Bottle/can height | customized |

| Bottle/can diameter | customized |

| Bottle/can shape | round, square, oval, rectangular |

| Main engine weight | 500kg |

Elements brand

| Item | Brands and material |

| sensor | transparent bottle sensor from Leuze Germany |

| PLC | SIEMENS |

| Touch screen | SIEMENS |

| breaker | Schneider |

| Rack | SUS304 |

| bearings | Japan NSK, original imported |

| Air switch | Schneider |

| replay | Omron |

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Price and Efficient Service" for Hot New Products Double Side Labeling Machine - Sleeve and shrink machine – Brightwin , The product will supply to all over the world, such as: Uganda, Paraguay, Thailand, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

Write your message here and send it to us