Massive Selection for Piston Filling Machine - Granule weighing and filling machine – Brightwin

Massive Selection for Piston Filling Machine - Granule weighing and filling machine – Brightwin Detail:

Overview

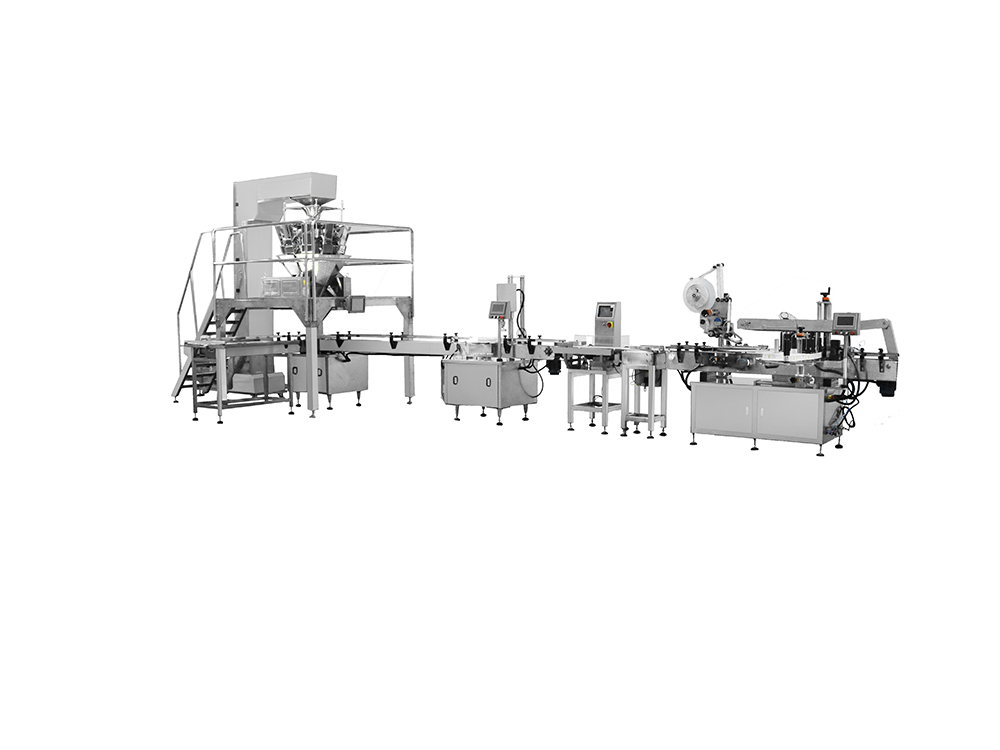

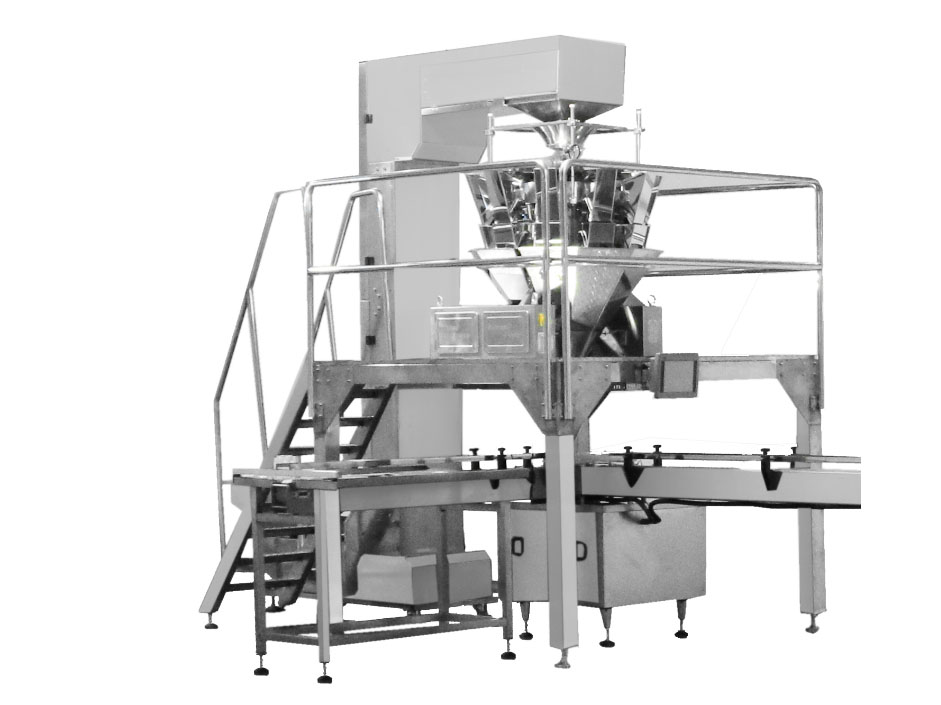

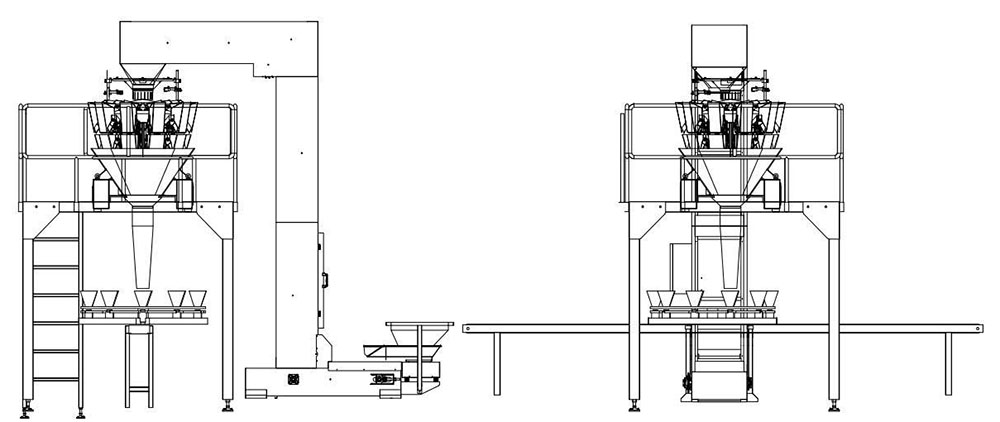

This machine will use SUS316 for product contact parts. Program recovery function can reduce operation failure. Adopts Tread Patterns type weigher, and the vibration hopper is 75 angle incline. PLC control, easy to operate, no bottle, no filling. All the hoppers can be opened make cleaning easy and quick; The weigh hopper can be preset to open in order (staggered) to avoid blockages with puffy or problem products. Multilanguage control panel, Spanish, Korea, German, French and Arabic, etc. The function of measurement by counting pieces or components to satisfy your various requirements.

This platform is beautiful, strong, has prevent slippery mesa, practical and safety. Mainly made of 304 stainless steel which is clean and health.

Most of all, the machine equipped with electronic combination weighing machine. It is important equipment for the automatic quantitative packaging system.

(Granule filling line can finish weighing, filling, capping, sealing, weight detecting and labeling etc. It is applicable for various containers like plastic bottles, glass bottles and cans etc.)

Feature

1.The weight in each bottle can be set in touch screen.

2.Can use different model of electronic scale according to different weight and capacity.

3.The whole line is adjustable, it is suitable for different bottle sizes and shapes by adjusting or change some parts.

4.It is designed and manufactured according to customers’ different products, containers and requirements like capacity etc.

5.The electrical elements brands can be customized.

6.The voltage is customized

Parameter

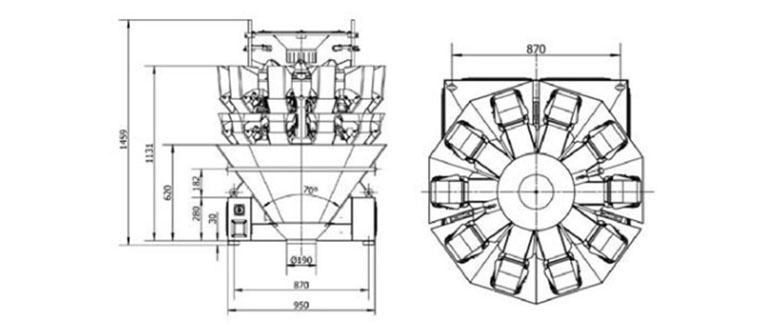

Weigh range:10-500g*n

Precision:0.5-2g

Max speed: 40-50 times/min

Power: 220V, 50HZ

Hopper volume:1.3L

Diamension:1436*1086*1258mm

Product detail pictures:

Related Product Guide:

With our excellent management, strong technical capability and strict quality control system, we continue to provide our clients with reliable quality, reasonable prices and excellent services. We aim at becoming one of your most reliable partners and earning your satisfaction for Massive Selection for Piston Filling Machine - Granule weighing and filling machine – Brightwin , The product will supply to all over the world, such as: Mauritius, Johannesburg, Venezuela, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.