New Delivery for Automatic Lubricant Filling Machine - Granule weighing and filling machine – Brightwin

New Delivery for Automatic Lubricant Filling Machine - Granule weighing and filling machine – Brightwin Detail:

Overview

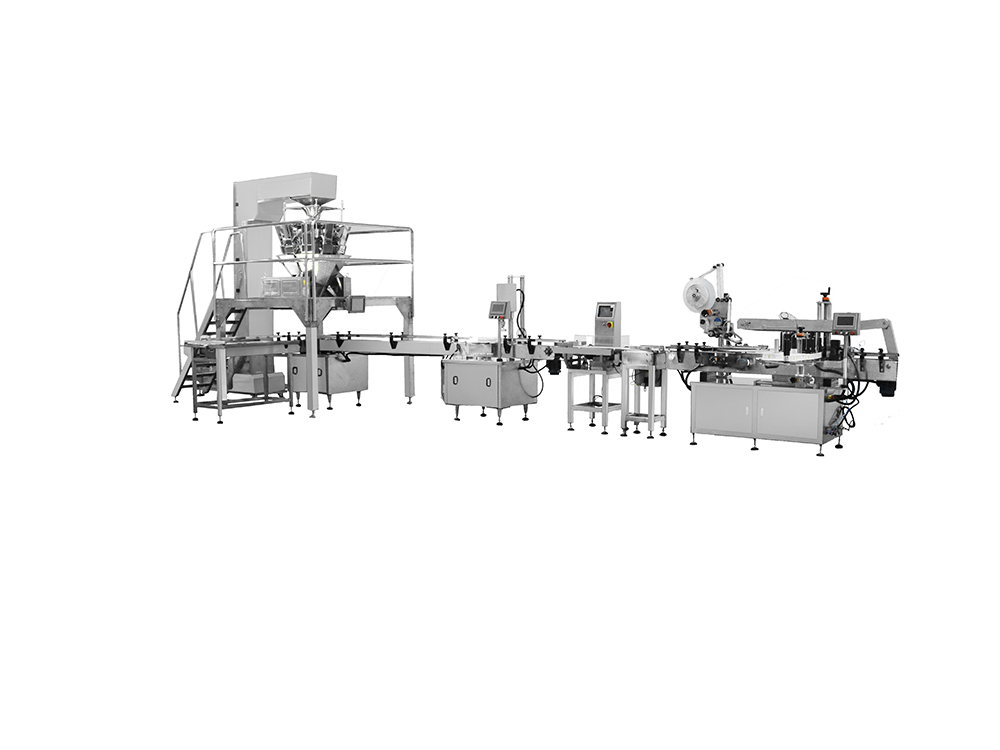

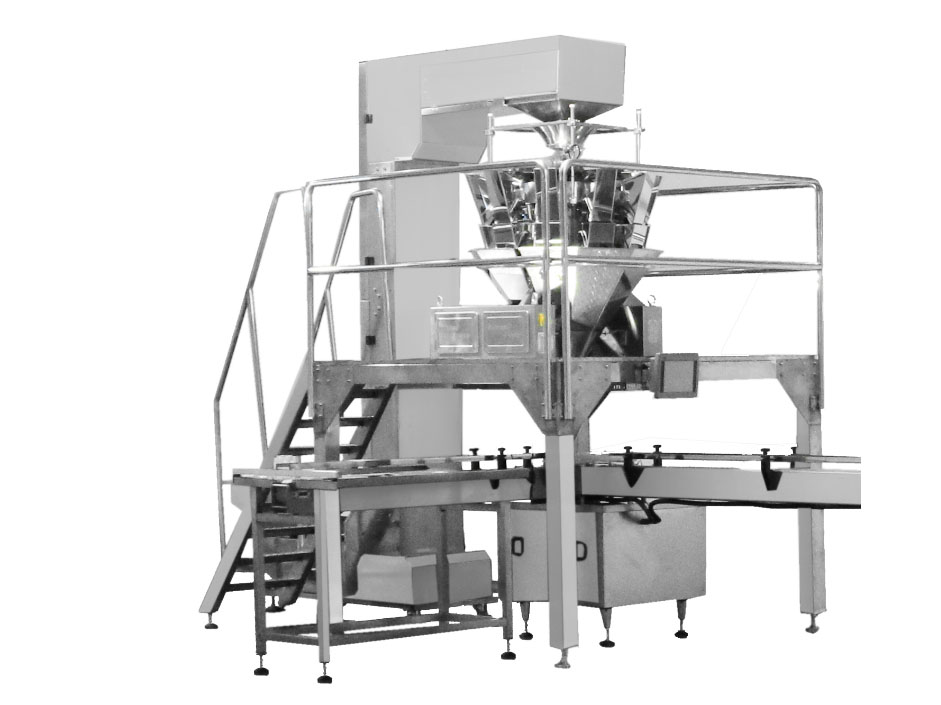

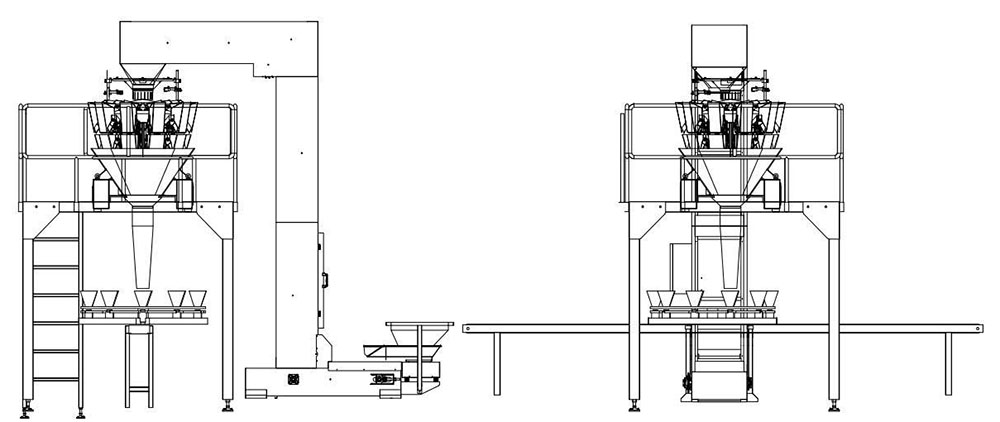

This machine will use SUS316 for product contact parts. Program recovery function can reduce operation failure. Adopts Tread Patterns type weigher, and the vibration hopper is 75 angle incline. PLC control, easy to operate, no bottle, no filling. All the hoppers can be opened make cleaning easy and quick; The weigh hopper can be preset to open in order (staggered) to avoid blockages with puffy or problem products. Multilanguage control panel, Spanish, Korea, German, French and Arabic, etc. The function of measurement by counting pieces or components to satisfy your various requirements.

This platform is beautiful, strong, has prevent slippery mesa, practical and safety. Mainly made of 304 stainless steel which is clean and health.

Most of all, the machine equipped with electronic combination weighing machine. It is important equipment for the automatic quantitative packaging system.

(Granule filling line can finish weighing, filling, capping, sealing, weight detecting and labeling etc. It is applicable for various containers like plastic bottles, glass bottles and cans etc.)

Feature

1.The weight in each bottle can be set in touch screen.

2.Can use different model of electronic scale according to different weight and capacity.

3.The whole line is adjustable, it is suitable for different bottle sizes and shapes by adjusting or change some parts.

4.It is designed and manufactured according to customers’ different products, containers and requirements like capacity etc.

5.The electrical elements brands can be customized.

6.The voltage is customized

Parameter

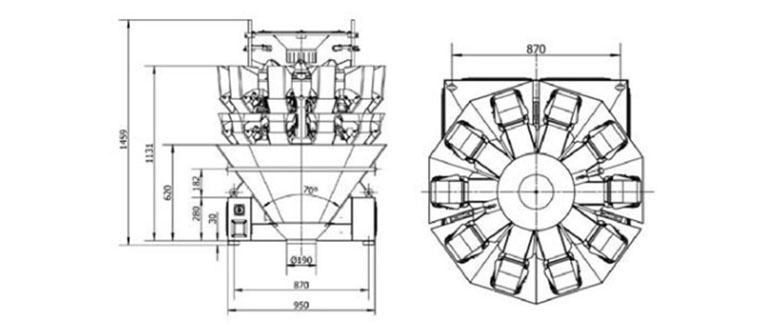

Weigh range:10-500g*n

Precision:0.5-2g

Max speed: 40-50 times/min

Power: 220V, 50HZ

Hopper volume:1.3L

Diamension:1436*1086*1258mm

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for New Delivery for Automatic Lubricant Filling Machine - Granule weighing and filling machine – Brightwin , The product will supply to all over the world, such as: Adelaide, Germany, Nairobi, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.